Crossdock Warehouse for Beginners

Table of ContentsThe Main Principles Of Sacramento Crossdock More About Sacramento Crossdock WarehousingGetting My Sacramento Cross Dock To WorkThe 3-Minute Rule for Sacramento CrossdockWhat Does Sacramento Crossdock Mean?The 3-Minute Rule for Sacramento Crossdock Warehousing

By establishing and also achieving stockroom objectives, a company can improve its general operations and also bottom line. What are some goals for storage facilities and how do they aid with business technique? It is typically not the case. It is critical that warehousing objectives remain in sync with business purposes if the company wants to make the most of profits, revenue, as well as margins.It is important to note that the goals are in dispute with business tactical goals. Stockroom employees required that shop supervisors discount paper products in order to meet transportation goals.

The objective of the storehouse supervisor was to boost effectiveness, property use, as well as consumer fulfillment. Supervisors might need to reset warehouse goals in order for the whole supply chain team to accomplish corporate objectives.

A Biased View of Sacramento Warehouse

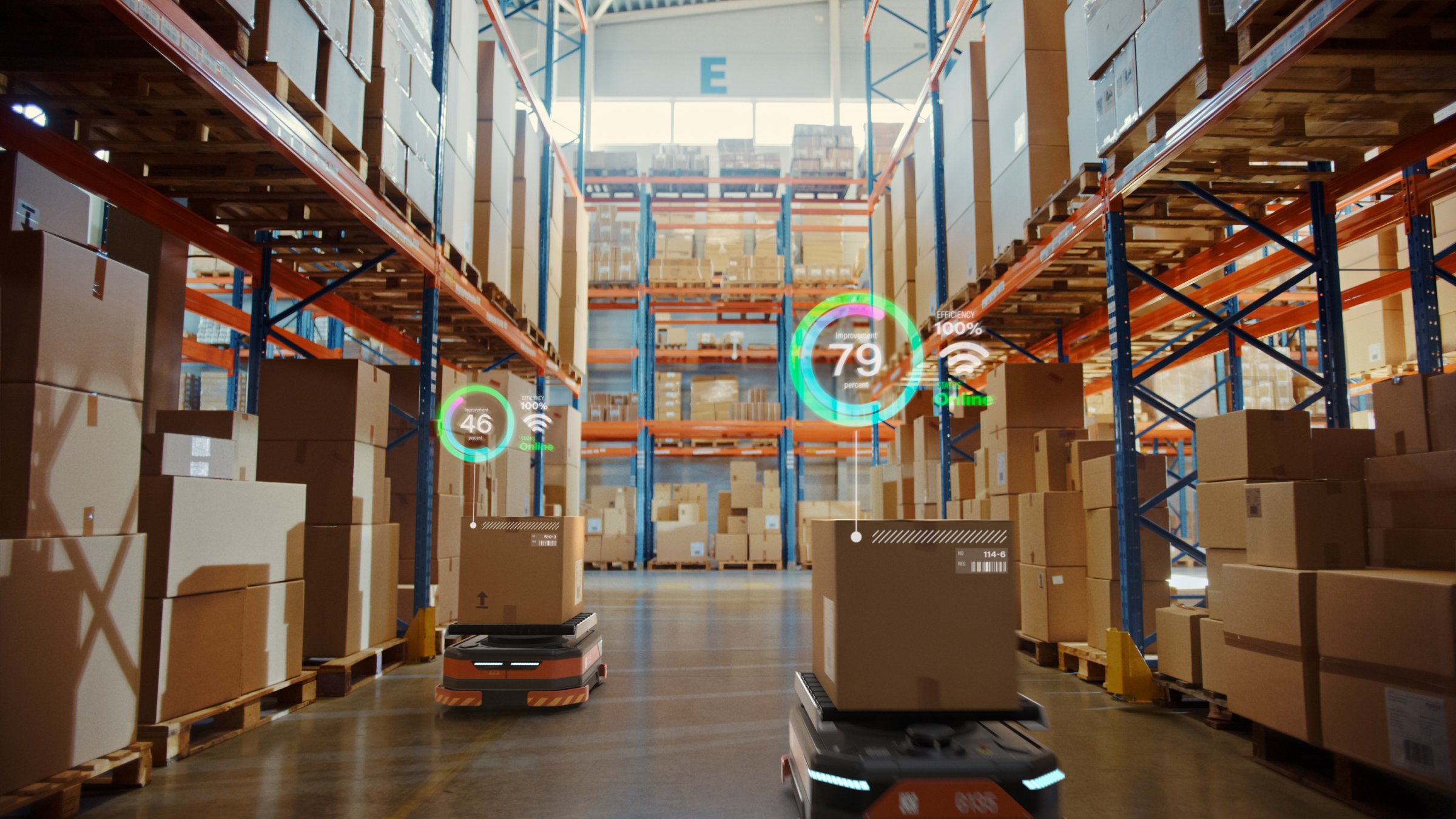

Supply chains can successfully handle their stock and also gratification services with cloud-based storage facility management systems. When it comes to third-party logistics, the supply chain is usually utilized along with stockroom administration systems. Having a robust system can allow warehouse managers to maintain every little thing on the right track and also simplify their operations.

Choosing lists for the function of recuperating things much more successfully ought to be carried out in stockrooms. To function appropriately, storehouse procedures must have the ability to obtain stock or products from service providers when loading docks are open. Every box as well as thing in a box should be scanned by a warehouse administration system.

In a current storage facility case research, it was shown that by utilizing a much more effective storage space system, the firm had the ability to improve its bottom line by 15%. This was accomplished by minimizing the quantity of time required to locate as well as get inventory, in addition to minimizing the quantity of labor called for to keep the stockroom organized. Sacramento Crossdock Warehousing.

See This Report on Sacramento Crossdock

Warehousing as well as activities, which are frequently referred to as "transportation at no miles per hr," take around 20% of overall logistics distribution expenses; consequently, they compel logistics executives to offer them major factor to consider. Warehousing is typically made use of at 2 points in the logistics chain. Basic material (such as coal, iron, ore, steel, gold ore, or sugar cane) might be stored in a stockroom before they are processed in a factory; they might also be kept as ended up products after they have been refined.

An appropriate meaning of warehousing then would be: Warehousing is a system of storing products en course from their factor of beginning (as raw products) to their factor of usage (as completed products). Due to the fact that need for products can not be forecasted with certainty and also they Visit Website can not be supplied quickly, storing inventories is unpreventable.

A lean system is when a company chooses to have a minimum quantity of stock on hand to keep the cost of inventory as well as warehousing fairly reduced. A business with a lean supply system only purchases materials or steps item when there is need from a customer. Lean inventories typically indicate that the cost of basic materials, warehousing and supply administration is less than various other systems.

Not known Details About Sacramento Cross Dock

When stock information is inaccurate, you could get an extreme or inadequate amount of raw products required for manufacturing or overproduce goods when it is not necessary. When stock levels obtain low in a storehouse, a lot of services would commonly send more item. However, with no efficient system in place for stock, some businesses might miss out on the mark and also incur unnecessary warehousing expenses.

It better makes the stock administration process much more efficient. Warehousing is optimal for businesses trying to get even more ordered as well as suit supply with need.

As an element of SCM, efficient inventory management might cause a more powerful supply chain. An additional reason good warehousing is vital to SCM is that it supplies a way for businesses to make certain the schedule of the ideal products at the proper their explanation location whenever the time is right. Sacramento Cross Dock. It enhances the energy worth of the goods by doing this.

3 Simple Techniques For Crossdock Warehouse

Of course, they become much more hesitant when unpredictability exists around the prompt distribution of items. Nowadays, distribution rate seems to be one of the significant factors that customers think about when choosing an item as well as making a decision whether or not to proceed with the acquisition.

A significant factor to purchase constructing a stockroom is the numerous known economic advantages that come with it. Not just the boosted efficiency of the supply chain but likewise the storehouse's storage capacity and also exactly how it acts as a main place for your products contribute to its economic benefits.

These points might be seen or understood with debt consolidation and also build-up operations. Here's a closer take a look at how combination and accumulation could help discover this reduced costs: With combination operations, there's no need to deliver items independently from multiple resources because they might be supplied to your storehouse as supplies. When an order is positioned, you or your staff can load and deliver the item out from there.

Things about Crossdock Warehouse

Not only that, however excellent warehousing likewise improves consumer service and also supplies economic benefits. Every one of these points can result in greater revenue and also boosted business productivity.